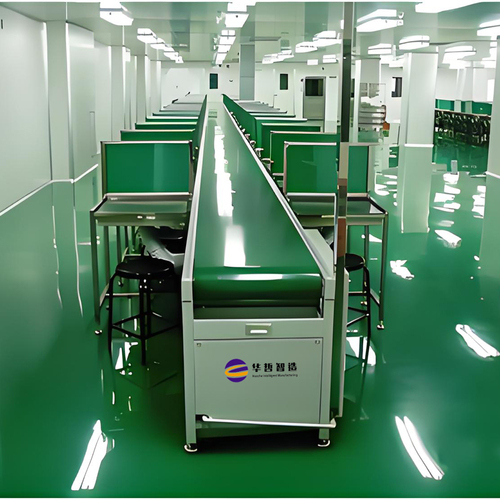

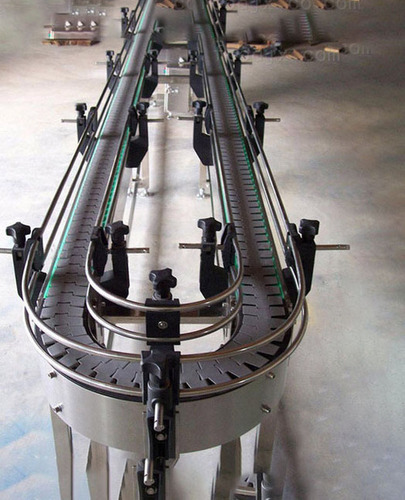

Factory produce Intelligent efficient cheap multifunvtion PVC/PU belt conveyor line

Product Details:

- Product Type belt conveyor

- Length custom Meter (m)

- Size custom

- Height custom Meter (m)

- Color custom

- Width custom Meter (m)

- Voltage custom Volt (v)

- Click to View more

Factory produce Intelligent efficient cheap multifunvtion PVC/PU belt conveyor line Price And Quantity

- 1000 USD ($)/Set

- 1500.00 - 3000.00 USD ($)/Set

- 1 Set

Factory produce Intelligent efficient cheap multifunvtion PVC/PU belt conveyor line Product Specifications

- custom Meter (m)

- belt conveyor

- custom Meter (m)

- custom

- custom Meter (m)

- custom

- custom Volt (v)

Factory produce Intelligent efficient cheap multifunvtion PVC/PU belt conveyor line Trade Information

- Shenzhen

- Paypal Telegraphic Transfer (T/T)

- 1000 Set Per Month

- 10 Days

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

1. Large conveying capacity, simple structure, easy maintenance

2. The components and structure of the belt conveyor line are standardized, which is conducive to reducing manufacturing costs and greatly shortening the manufacturing cycle of the equipment.

3. The design of the belt conveyor line makes there is no relative movement between the material and the conveyor belt, so the damage to the conveyor can be avoided during the conveying process.

4. The structure of the belt conveyor line is simple, which makes it easy to maintain and maintain. In the event of a problem, maintenance personnel can quickly locate and resolve the problem, thereby reducing line downtime.

5. The energy consumption of the belt conveyor line is small, which means that in the long-term operation process, its use cost is lower.

6. The width and length of the belt conveyor line can be adjusted according to the needs of the production beat, so as to adapt to different production needs.

7. The conveyor belt of the belt conveyor line can be made of rubber, silicone, PVC, PU and other materials. These materials can not only meet the conveying of ordinary materials, but also meet the conveying of materials with special requirements such as oil resistance, corrosion resistance, and anti-static. In addition, there are special food-grade conveyor belts, which can meet the requirements of food, pharmaceutical, daily chemical and other industries.

8. The noise of the belt conveyor line is small, which is suitable for the occasions where the working environment requires relatively quiet.